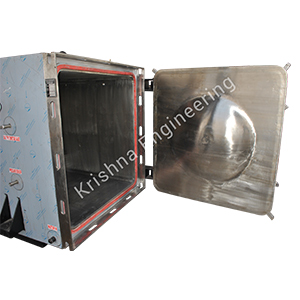

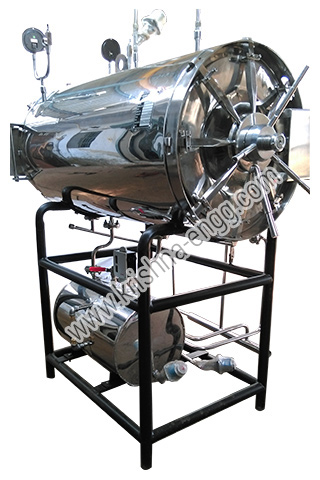

Incepted years ago in this domain, we are leading manufacturer, supplier and exporter of Dry Heat Sterilization which refers to any process that removes, kills or deactivated all forms of life such as microorganisms such as fungi, bacteria, viruses, spores, unicellular eukaryotic organisms such as Plasmodium. Sterilization by dry heat has become increasingly popular across the globe due to two main special factors that needs of sterilizing small objects, especially ampoules, syringes and secondly for de-progenation of manufacturing apparatus which is impossible in a steam sterilizer. Dry heat sterilization and dehydrogenation process is mainly used for complete destruction and removal of all micro-organisms by means of dry heat. These stainless steel dry heat sterilizers use air as a medium of sterilization

| Ampoules Vials | Metal and glass Vials |

| Schering bottles | Aluminum caps |

| Injection bottles | Infusion bottles |

| Filters | Textiles |

| Garment | Bandage |

| Gauze | Stoppers |

| Metal containers | Equipment parts |

| Dry powder drugs | Oil and wax |

Krishna Engineering offers Dry Heat Sterilization which are ideal for Pharmaceutical and allied industries, laboratories, research institutes, food industries, etc. These offered Dry Heat Sterilizations are designed for safe and efficient sterilization. The Sterilizer is normally suitable to operate in temperature range of 160°C-180°C to 250°C/270°C. The chamber has Glass Wool insulation & it is covered with Stainless Steel Outer Cover.

This will reduce external unit temperature. Sterilizer can be supplied with stainless steel removable shelves/ trays or with a loading carriage & trolleys. As we have in-house manufacturing of dry heat sterilizers (hot air sterilizer), we offer our customers a wide range of customization facilities essential to make your work easier, while ensure optimum performance and user flexibility in the most demanding conditions.